Product Description

CNC Reinforcement Pile Steel Rebar Cage Welding Making Machine

CNC rebar Cage making Machine by automatically expect points on material; Rack main reinforcement artificial to through the fixed disc catheter to mobile plate duct, and pass by electric tools will be the main reinforcement fixed on the mobile disk catheter,coils after straightener welding on the main reinforcement; And then start the normal welding, fixed plate and plate of synchronous rotation and movement plate according to the preset speed (walking speed can be adjusted according to the operation of the workers' proficiency in), welding at the same time, to make the finished steel reinforcement cage.

Equipment model | FH1500 | FH2000 | FH2500 |

For the pile diameter(mm) | 600--1500 | 800--2000 | 1000--2500 |

Reinforcing cage standard length(m)other lenght ,can be made as clients' requirements | 12 18 22 27 | 12 18 22 27 | 12 18 22 27 |

Cage weight(kg) | 4500 | 6000 | 8000 |

The main reinforcement diameter(mm) | Φ12--Φ40 | Φ12--Φ40 | Φ12--Φ40 |

Disc diameter(mm) | Φ6--Φ16 | Φ6--Φ16 | Φ6--Φ16 |

Spiral Pitch(mm) | 50--400 | 50--400 | 50--400 |

The welding way | Carbon dioxide protection welding | Carbon dioxide protection welding | Carbon dioxide protection welding |

Hydraulic station parameters(Mp) | 8 | 8 | 8 |

The power supply parameters | 380v 50hz | 380v 50hz | 380v 50hz |

Power(Kw) | 13, the most powerful production power of 10 | 23, the most powerful production power of 18 | 29, the most powerful production power of 23 |

Main Features

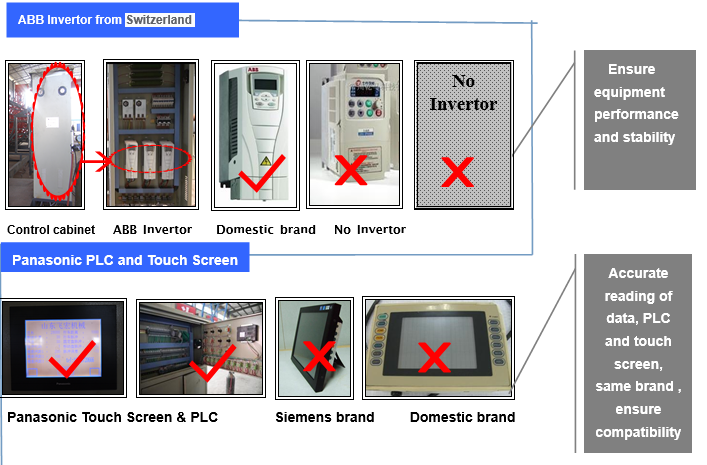

1.Control System:adpot Import ABB invertor and Panasonic PLC and Touch Screen electronic control components to ensure the stable operation of the equipment.

2.Easy to operate, user-friendly, three persons can work.

3. Cage diameter error control precision, the line rebar spacing error is small, can be controlled within 1cm; one meter coils spacing error can be controlled within 5mm。

4. Can produce double longitudinal bar with double spiral wires high quality rebar cage.

5. Excellent workmanship and strict quality inspection, high precision, wear resistance, the easy maintenance and long service life.

6. The weight of the whole machine is 1/3 more than that of the same kind of equipment in the industry.

7. The hydraulic system is designed specially, adopted the hydraulic component which is in current use in the World, which is durable, and with high interchangeability.With more automatic hydraulic feed rollers, to prevent steel cage deformation due to its own weight。

8.Equipped with automatic feeding device, easy to operate and improve efficiency.

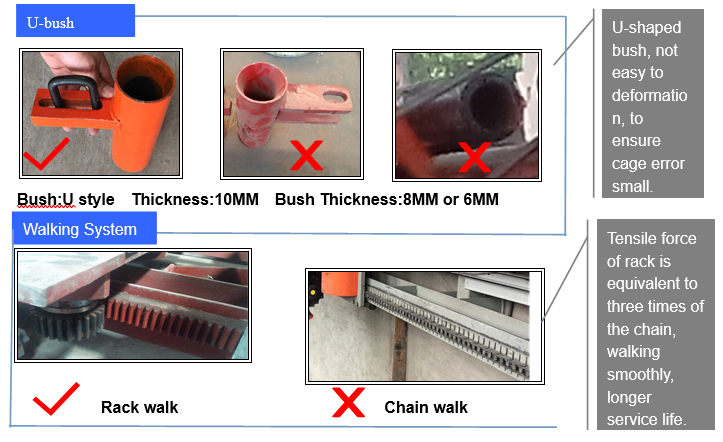

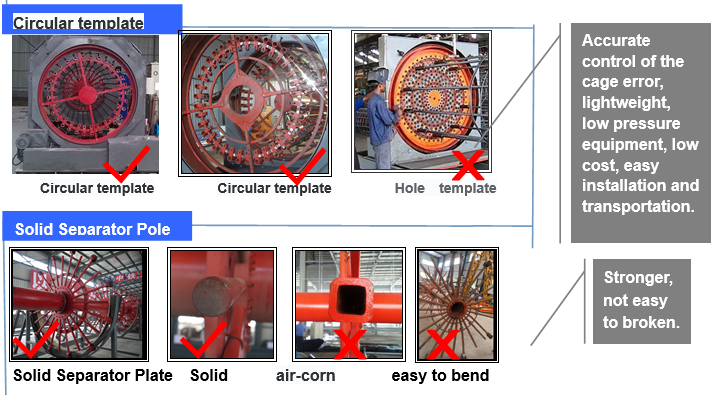

9. Template using the template ring plus U style catheter combination, can be quickly replaced and transform the quantity of main steel cage wire.

10. Outfitted for Accessory Equipment Arc bending Machine and CO2 Shielded Arc Welding.

11. BI-directional straightening arm are made of high strength alloy material, high strength, anti-wear and improve the life of wearing parts, can horizontal / vertical bidirectional adjustment of the coils to ensure the quality of the rebar cage.

Quick Details

Type:Other

Place of Origin:Shandong, China (Mainland)

Brand Name:JIAXIN

Model Number:FH1500 FH2000 FH2200 FH2500

Voltage:380V 50HZ 3Phase

Current:40A

Rated Capacity:23kw

Rated Duty Cycle:60%

Dimensions:26MX6MX2M

Weight:18000kgs

Usage:Welding Machine

Certification:ISO9001

Name:CNC Reinforcement Pile Steel Rebar Cage Welding Making Machine

Warranty:One Year

Cage diameter:600mm-2000mm

Length of cage:2000- 18000mm

Color:orange,blue,grey .....

Coils Diameter:5~16mm

Line-rebar diameter:12 ~40mm

Working temperature:0 ~40℃

Hydraulic system:10Mp

Welding:CO2 shielded arc welding

After-sales Service Provided:Engineers available to service machine