CNC bending machine working principle

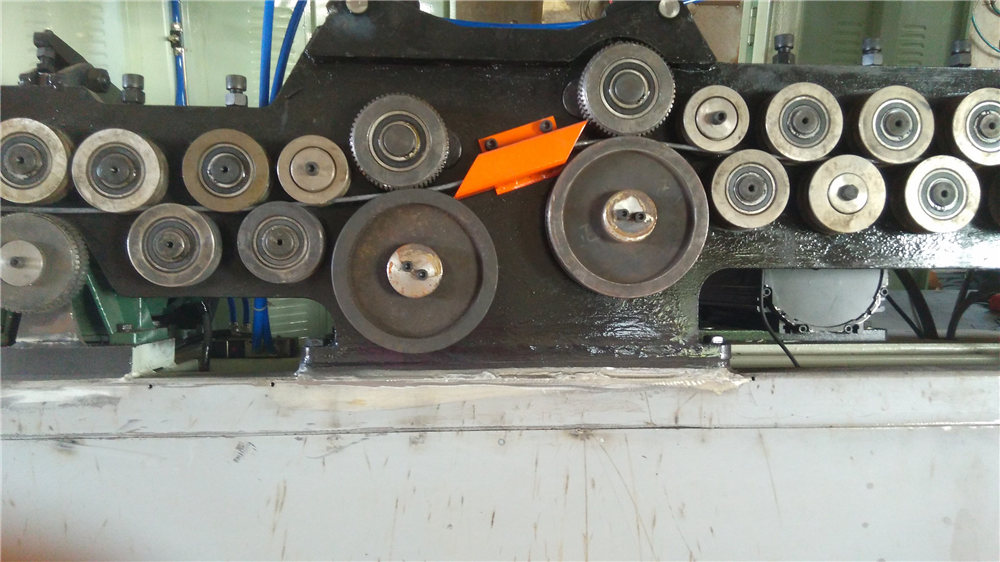

♦ Fully automatic CNC bending machine and steel hoop machine, the straightening system has the following characteristics: two sets of straightening rolls automatically adjusted horizontally and vertically, combined with 4 traction wheels, driven by servo motor to ensure the best straightening precision of steel bars . Among them, the steel bar processing machine and the CNC wire bending machine belong to a structure of steel bar bending machine.

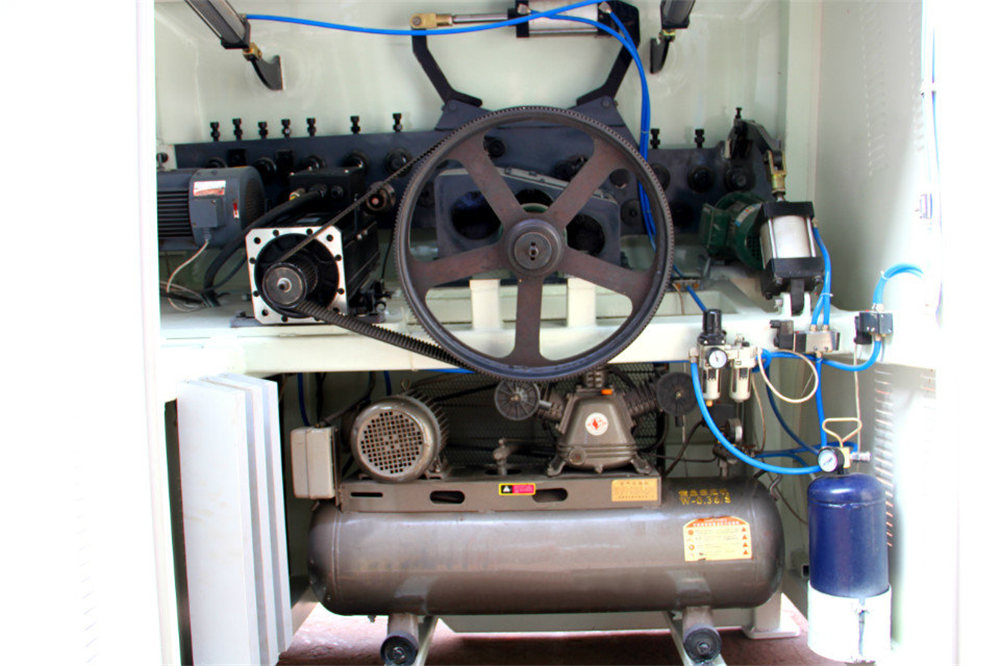

The utility model comprises a reducer, a large gear, a pinion gear and a curved magnetic disk. The characteristics of the structure are: two-stage brake motor, a reducer and a slowing level; a small gear reduction cooperation large gear tooth 2 large gear Always bend the disk wheel, when the curved disk surface sets a center, and a few bends, the positioning work surface is bare in the set, respectively, when there are several orientations. Thanks to the double brake motor, reducer and class 1, the input-to-output ratio is accurate, the bending speed is stable and accurate, and the electrical automatic control can be used to change the speed, and the brake can guarantee the bending angle. Using positive and negative, the motor's bi-directional reinforcement bends.

Fully automatic CNC wire bending machine and steel hoop bending machine, the straightening system has the following characteristics: two sets of straightening rolls automatically adjusted horizontally and vertically, combined with 4 traction wheels, driven by servo motor to ensure the best straightening precision of steel bars .

Among them, the steel bar processing machine and the steel bar bending machine belong to a structure of steel bar bending machine. The utility model comprises a reducer, a large gear, a pinion gear and a curved magnetic disk. The characteristics of the structure are: two-stage brake motor, a reducer and a slowing level; a small gear reduction cooperation large gear tooth 2 large gear Always bend the disk wheel, when the curved disk surface sets a center, and a few bends, the positioning work surface is bare in the set, respectively, when there are several orientations. Thanks to the double brake motor, reducer and class 1, the input-to-output ratio is accurate, the bending speed is stable and accurate, and the electrical automatic control can be used to change the speed, and the brake can guarantee the bending angle. Using positive and negative, the motor's bi-directional reinforcement bends.

CNC Wire bending machine function

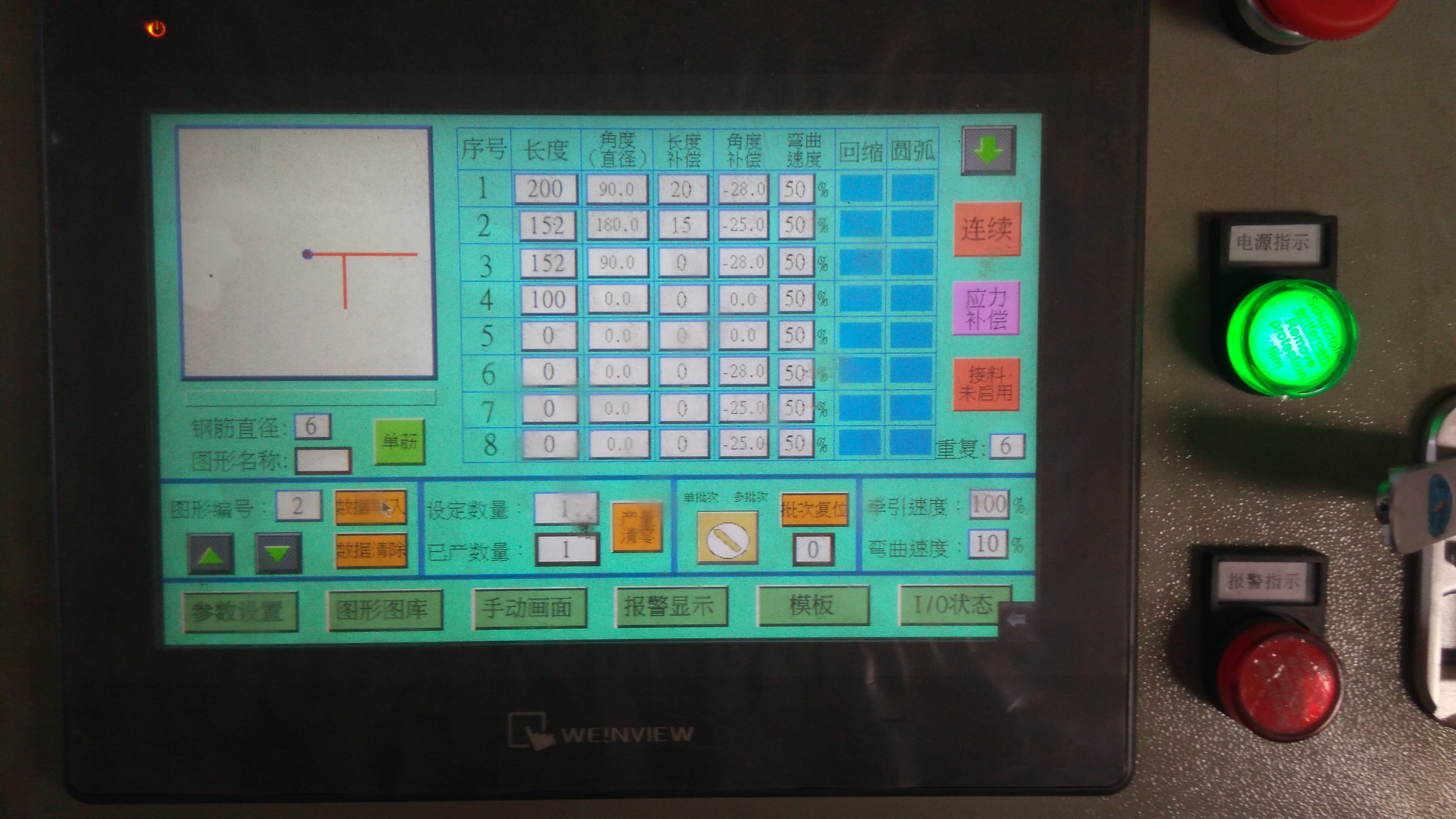

The machine adopts CNC servo control system, which can automatically complete the steps of straightening, sizing, bending and cutting of steel bars. It can bend the maximum diameter of 16mm steel bars and continuously produce any flat shape products. It is widely used in construction industry, large steel processing factory. And other fields.

CNC wire steel bar bending machine safety operation procedures

The CNC wire bending machine is a highly automated equipment. The whole machine and the squatting machine are integrated with the main machine. The production process is basically done automatically by the system. If the equipment is unfamiliar to the machine, it will cause accidents, which will result in personnel or The damage of the machine, so the operator of the equipment must be strictly trained, familiar with the functional characteristics and operation methods of the machine, and operate in strict accordance with the requirements of the manual.

♦ Prepare before starting up

An operator must wear a safety helmet and protective gloves, otherwise it is not allowed to enter the scene.

Second, confirm that there are no other non-operators around the machine to prevent accidents from causing irreparable consequences.

Third, the position makes the equipment have good working conditions, and the lubricating parts should be greased before starting the machine.

Fourth, check whether the lubricating oil in each box reducer is sufficient. The lubricating oil should be in the middle of the oil mark. If the oil level is too low, the lubricating oil should be replenished in time.

♦ Check if there is loose screw in each part, check if the air source is connected to the PE line and connect to the location.

♦ Sixth, check each electrical circuit switch, check whether the switch is normal, check whether the gas path is intact.