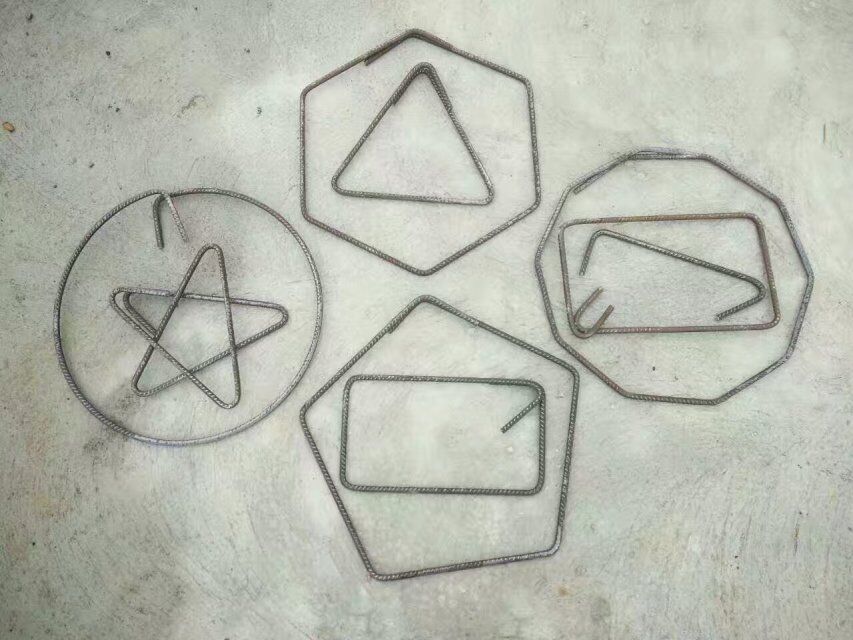

CNC stirrup bender machine is low failure rate, fast speed, low energy consumption ,low noise and light vibration; CNC stirrup bender machine has the characteristics of high efficiency, reliable operation and so on. The operation is light and flexible, and the movement is convenient. CNC stirrup bender machine is suitable for the large construction production units and rebar processing factories. CNC stirrup bender machine has high efficiency and can produce 4-6 tons per day. The fixed length is suitable for large batches and factory operations, and the angle adjustment range is wide. CNC stirrup bender machine can adjust from 0-180 degrees, CNC stirrup bender machine can bend square, trapezoidal stirrups and U-shaped hooks, CNC stirrup bender machine is suitable for stirrup processing of buildings, bridges, tunnels, prefabricated components, etc.

The CNC stirrup bender machine can meet the requirements of processing single-line diameter of 4~12mm steel bar and double-line diameter of 5~10mm. In addition, CNC stirrup bender machine has been improved after several times of production, and CNC stirrup bender machine can meet the actual steel processing and production needs. The details show the pursuit and solve the practical problems.

Advantages of CNC stirrup bender machine

1. It consists of two sets of straightening wheels that can be adjusted automatically horizontally and vertically. CNC stirrup bender machine combined with 4 traction wheels and it is driven by imported servo motor to ensure the straightening of the steel bar to achieve the best precision.

2. Bending and shearing mechanism: CNC stirrup bender machine is driven by imported servo motor, the bending arm can rotate and telescope at high speed, and the shearing mechanism can complete the shearing action at high speed to ensure the bending precision of the steel bar.

3. Control system: CNC stirrup bender machine adopts foreign mature control system with high reliability. The control system has fault identification and alarm functions.